When roads cross hilly areas and the roads are made in deep cut, the excavation may open springs and seeps in mountain aquifers or in saturated soil layers (see Section 5.3). These newly opened springs can damage cut slopes and erode land. On the other hand, they can provide a safe water supply source (García-Landarte Puertas et al. 2014). To ensure that water quality is not threatened and that there is no damage to roads, springs need to be protected.

The following issues should be considered when a potential spring source is investigated:

- Understand the nature of the spring

- Ensure that the spring is not a stream that has gone underground and is re-emerging.

- Ensure that the source and the collection area are not likely to be polluted by surface runoff.

- Check that there are no latrines within 30 m, particularly upstream of the spring.

- Fence the area around the spring tank to prevent pollution.

- Make sure that, if the spring is to be connected to a piped water system, it is on higher ground than the area to be supplied so that the water will flow with gravity.

- Take care that the spring tank is not built on swampy ground or on land that is subject to erosion or flooding, and that the flow from the protected spring will not cause erosion or damage the road.

- Develop a ‘captage’ structure.

It is crucial to protect the catchment of the spring and the spring head from pollution, and to arrange for the spring water to be delivered at an appropriate height so that water falls with gravity directly into a container. An inspection of the ground upstream of the spring is essential to ensure that there is no danger of pollution or, if there is, to identify measures to prevent it.

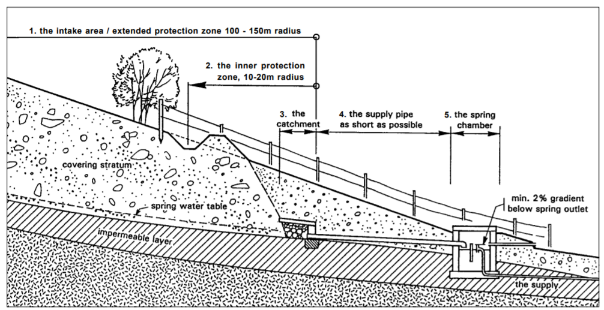

To protect the spring, a fenced inner protection zone (with a radius of 10m to 20 m) should be established, and all activities posing a risk of contamination should be restricted (e.g., farming, grazing, burning, application of pesticides and fertilizers, construction of latrines, use of chemicals, etc.). The area should only be planted with grass. All trees and bushes should be uprooted, since roots can damage the catchment by cracking the structures or by blocking the pipes.

Springs can be protected by installing a spring tapping, a spring box, and a drainage system. Moreover, a surface-water drainage ditch should be dug above and around the spring area to keep surface water runoff from polluting the source. If the area around a spring intake is unstable or exposed to erosion, gabions or dry stone masonry can be used to stabilize the area.

Protection boxes (Figure 6.3) for newly opened springs collect the spring water, which can either be diverted to infiltration structures (such as soakways) or used directly in storage structures such as open ponds or cisterns. It is important to estimate the spring’s flow rate to properly determine the dimension of the collection tanks and create spillover structures.

Box 6.4 describes the advantages of protecting the springs.

Box 6.4 Advantages of spring protection schemes

✓ Water coming naturally to the surface limits need for pumping

✓ Low maintenance and operating costs

✓ Can be a high-yielding source of good quality: no need for treatment

Disadvantages of spring protection schemes

✗ Yield can diminish or dry up during extreme drought periods

✗ Regular maintenance is needed around the spring head to prevent pollution

Source: WaterAid 2013

A safe source spring should not have an increase in flow directly after heavy rainfall, but rather a few weeks later. If the flow increases after rains, it implies that rainwater flows quickly through the ground and the purification effect is insufficient to remove small and pathogenic bacteria. This type of spring is unsuitable for drinking water.

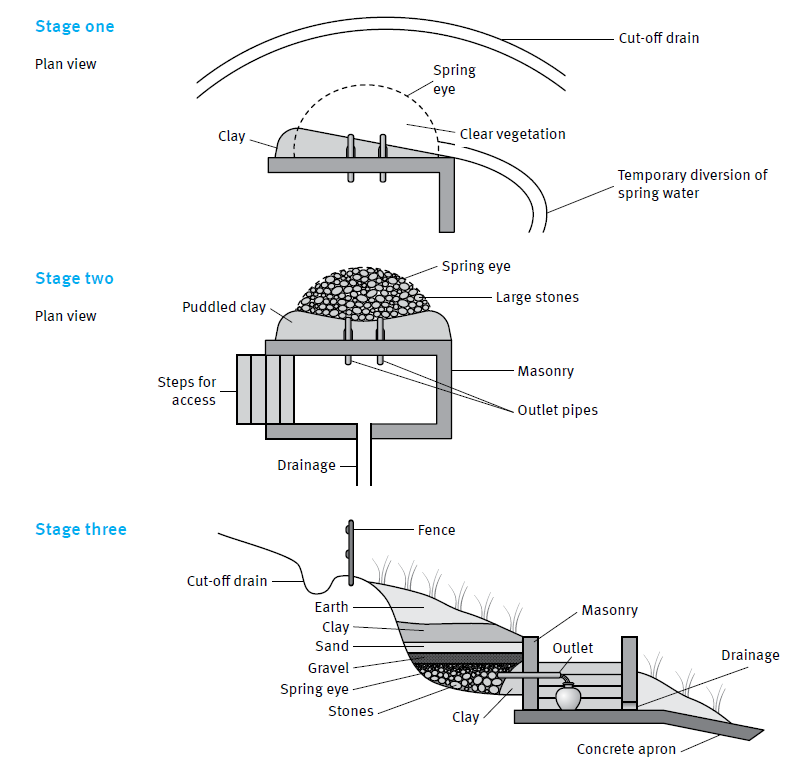

Figure 6.4 illustrates the stages in the construction of a spring collecting chamber.

Stage one:

- Clear vegetation above the head of the spring;

- Build a cutoff drain to divert surface water; and

- Divert the spring water temporarily to allow construction of the collection chamber.

Stage two:

- Place large stones above the head of the spring; and

- Construct the collection chamber.

Stage three:

- Further protect of the spring head with layers of impervious material above it.

The supply pipe transports all of the spring flow from the catchment to the spring chamber. The pipe should be able to transport the maximum spring yield without stowing it back in the catchment. If the supply pipe becomes blocked, the spring source will build up pressure behind the catchment and flow to another outlet of lower resistance. This may cause the source to disappear completely.

Spring flow rates

Seasonal rainfall variations influence spring yield. Seasonality should be studied when designing the spring system to ensure that enough water will be available during the dry period of the year. To determine the reliable yield of a spring, it is necessary to measure the spring’s flow at the end of the rainy season. A flow over 0.1 liter per second can fill a 20-liter container in over three minutes. If the flow is lower than 0.1 liter per second, a storage tank can be installed to enable the flow from the spring to accumulate. If the flow is 0.5 liters per second or more, the spring would be suitable to supply multiple outlets or a piped gravity scheme. The choice between an open or closed (with tank) distribution system depends on the spring’s capacity and the demand. When the demand is higher than the spring flow, a closed circuit with a storage tank should be installed. On the other hand, when the demand is lower than the spring flow, an open circuit without a tank is recommended.

The following guidelines should be kept in mind when designing the supply pipe:

- The distance between the catchment and the spring chamber should be as short as possible to reduce the chance of pipe blockage.

- The pipe must be laid as straight as possible and without vertical bends to prevent blockage.

- To prevent sediment buildup, the minimum supply pipe gradient from the catchment to the spring chamber is 3 percent.

- It is recommended that an overflow pipe 5 cm to 10 cm higher than the supply pipe be installed.

Operation and Maintenance

To ensure long-term usability of the spring, frequent maintenance of the spring area by a local caretaker and adequate operation by the community are needed (Bruni, Marco Spuhler 2018).

The tasks of the caretaker should involve:

- Inspection, cleaning, and repair of spring installations (e.g., cracks in the apron, leaking parts, etc.).

- Monitoring of activities in the surrounding area to avoid spring pollution.

- Upkeep of the protection zone/repair of the fence.

- Checking for appropriate operation by users.